There is a wide variance of views on whether the growth of machine intelligence – where machines learn to improve their own performance – will have a positive or negative impact on workers and jobs.

Whether it is fears over labour-intensive ‘human’ jobs being lost to intelligent machines, the trialling of driverless cars or even popular TV dramas such as Netflix’s ‘Black Mirror’ with its automated killer drone bees – there is a growing narrative suggesting the advancement of machines will come at a human cost.

Indeed, there is a prevailing view across most industries that automation in any form is a precursor to job cuts by its very nature.

Working in the manufacturing industry day-to-day however, the picture is somewhat different. Indeed, there is plenty of supporting evidence to suggest that the increase in productivity brought about by automation can only benefit companies’ bottom lines, which in turn will stimulate growth and new opportunities for employees to take on more strategic and idea-driven roles.

As the Harvard Business Review says in this article, there is a school of thought that suggests automation will make us rethink what a job really is.

If you needed more convincing, here are five more reasons to view automation as an undoubted net-positive for businesses and employees alike:

- 1. Turning disaster into triumph: Allied Hygiene, one of the largest independent manufacturers of wet and dry wipes in the UK, has been operating in Erith, Kent for over 25 years. In February 2015, a fire necessitated the company invest in a new production line. With support from Shemesh Automation, the factory was up and running again within much faster then anyone could have anticipated, with a more efficient production line based around the Shemesh Automation Xpander monoblock packaging machine. As well as reducing costs and utility consumptions, the small footprint has freed up factory space to allow Allied Hygiene to increase capacity, and grow the business.

2. Saving money, space and utility consumption through innovation

Beams Packaging Services in the UK faced a difficult challenge during their growth period. Having focused on a niche in filling and capping 50cl gin bottles they soon found clients wanted a wider range of bottle sizes and shapes. However, time and time again the market told them it would be impossible to deliver their entire range using one production line. Shemesh Automation stepped in to build a bespoke solution capable of satisfying all of Beams requirements, in just one line.

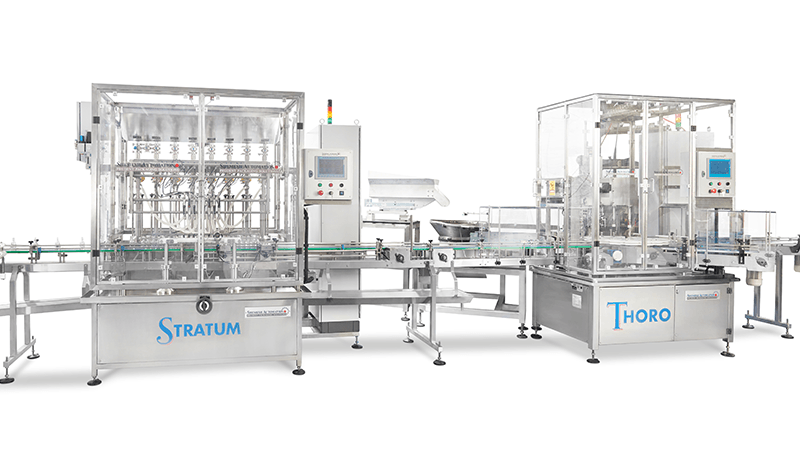

The capacity and speed of both the STRATUM automatic liquid filling machine and THORO automatic capping machine gave Beams the ability to seamlessly fulfil each product range with minimal downtime between runs, thus reducing costly capital outlays, space and utility consumption associated with multi production lines.

If you still need convincing about the benefits of automation – take a look at this short video and see what Beams Head Engineer Rick Lennard had to say.

3. Savings for you, and the environment. We’ve all heard about smaller footprints and reduction in utilities usage – but did you also know the latest technology is also helping to reduce raw materials wastage? To give just one practical example – using the latest laminate cutting and sealing machine may save up to 10 times the amount of raw materials used when running a pre-cut laminate and induction-sealing machine. In monetary terms, assuming a 60PPM production mode in just one shift, this translates to about 50,000 Euro per annum. Money which could be used to contribute to business expansion.

-

- 4. Cognitive Automation could free up of skilled workers to focus on innovation: Here, Cliff Justice of KPMG argues “for skilled workers, the impact [of cognitive automation] will be… transforming. Helped by cognitive software, generalists can behave like specialists and less experienced employees can perform like seasoned veterans”.

-

- 5. The quantity of available jobs could also be improved due to automation: As discussed in this article by Forbes, not only does automation have the potential to create new jobs in future, but also employees are already finding that “the mix of their work is changing to be less repetitive and more judgment-intensive”.

To reiterate, the main conclusion of this article is that the increase in productivity brought about by automation can only benefit companies’ bottom lines, which in turn will stimulate growth and new opportunities for employees to take on more strategic and idea-driven roles.

As Kweilin Ellingrud, senior partner at McKinsey & Co says in her Forbes article : “when automation can handle up to 45 percent of repetitive work, it gives workers time for more higher-value tasks such as problem-solving, finding solutions and developing new ideas. This will empower employees, and generate a more engaging and challenging work experience.”

To find out how industrial automation can reinvigorate YOUR business, contact for FREE advise us at: sa@shemeshautomation.com or visit www.shemeshautomation.com