Why Do Slow Packaging Lines Kill Profits?

When we talk about slow packaging lines, we refer to inefficient and fragmented production processes that rely heavily on manual or semi-automatic operations — especially during rolls Feed Conveyor, rolls stuffing, filling, sealing, capping, labeling and case packing.

Manual Processes: The Hidden Bottlenecks

In many wet wipes production lines, operators are still required to:

- Manually place empty canisters, buckets, or bags onto conveyors

- Manually stuff rolls of wet wipes into canisters or buckets

- Manually handle bucket lids and closures, bucket denesting or bag sealing

- Assist semi-automatic filling and capping processes, positioning each container before every cycle

These manual steps drastically slow down the entire line, creating production bottlenecks that limit output and prevent smooth, continuous operation.

Even when some steps like filling or capping are partially automated, the need for operators to intervene at every cycle — for instance, by positioning containers under the filling nozzles or placing caps before capping — breaks the flow and reduces efficiency.

The Problem with Semi-Automatic Systems

Semi-automatic solutions may look like a compromise, but they still suffer from:

- Stops and starts, waiting for manual placement of containers or rolls

- Slower overall speeds, limited by human interaction

- High labor costs, since more operators are needed to keep the line running

- Higher error rates, including misaligned containers or incorrectly filled/capped products

- Inconsistent production capacity, impossible to scale without adding more people

Result: slower production, higher costs, and lower profits.

Fully Automated Lines: The End of Bottlenecks

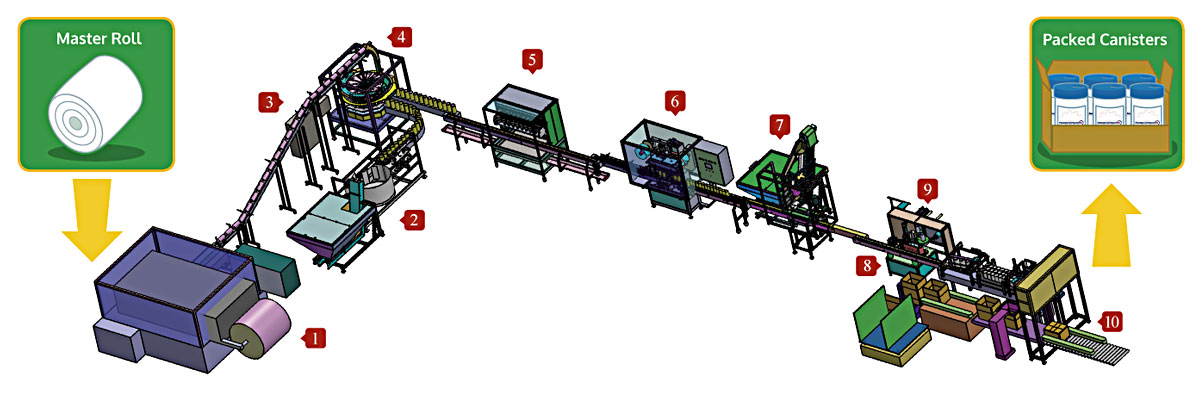

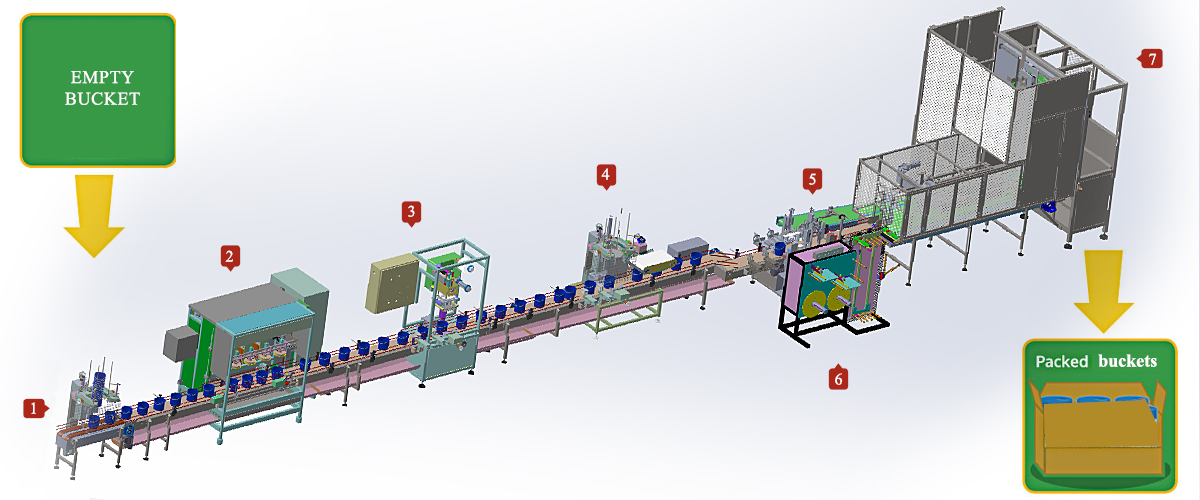

With fully automated wet wipes packaging lines, every step — rolls feed conveyor, rolls stuffing, filling, sealing, capping, labeling and case packing — is seamlessly connected in one high-speed, continuous process.

Automated feeding systems place empty canisters, buckets, and bags directly onto conveyors, ready for the next station.

Automated stuffing units insert nonwoven rolls into canisters with precision and speed, while fully automatic filling and capping systems ensure each container is filled to exact specifications and perfectly capped, without manual intervention.

Benefits of Full Automation:

- Continuous operation — no downtime waiting for manual placement

- Faster production speeds — optimized line performance

- Reduced manpower — lower operational costs

- Consistent quality — precise stuffing, filling, and capping every time

- Minimal errors and waste — greater efficiency

- Increased profits — higher output, lower costs

Let’s talk wet or dry rolled wipes in canisters, bags, or buckets. Make an appoitment here.

Packaging Solutions for Canisters

High-Performance Packaging Line for Canister

Packaging Solutions for Buckets

High-Performance Packaging Line for Bucket

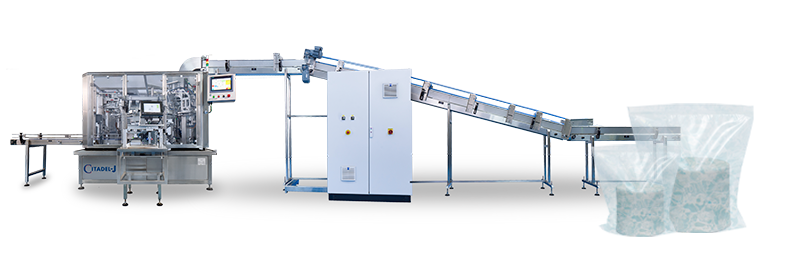

Monoblock for Refill or Jumbo Bags

Monoblock for Canisters

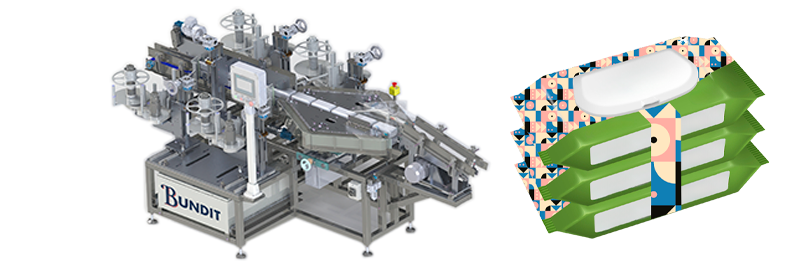

Automatic Stacker & Bundler

Why Choose Shemesh Automation Wet Wipes?

Conclusion

Manual and semi-automatic lines are holding your business back.

If you’re still manually placing containers on conveyors or stuffing rolls into canisters, you’re not just wasting time — you’re losing productivity and profits.

Shemesh Automation Wet Wipes offers fully automated lines that take care of every stage — from feeding and stuffing to final case packing — helping you maximize throughput, reduce labor costs, and ensure consistent, high-quality results.

Ready to upgrade your wet wipes production? Let’s talk.

Follow us on LinkedIn for updates on our latest innovations.