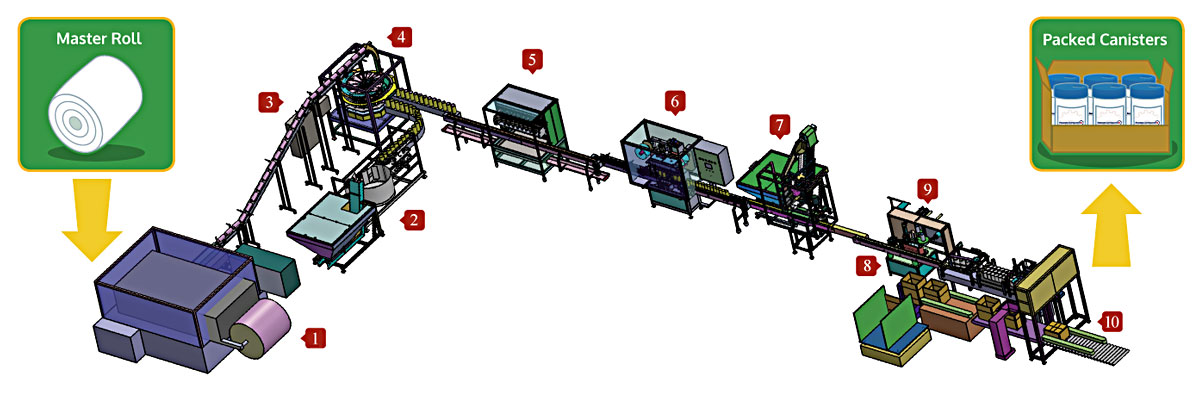

Complete Turnkey Solutions - Canisters

-

1

Converting Machine

-

2

Canisters Unscrambler (SA-CF120)

-

3

Rolls Feed Conveyor

-

4

Automatic Rolls Stuffer SAS120

-

5

Automatic Dosing & Filling Machine FGW120

-

6

Foil Cutting & Canisters Conduction Sealing Machine SEALPRO120

-

7

Automatic Capper CIW120

-

8

Full Wrap Around Labeler LWA120

-

9

Continuous Labels Rolls Magazine

-

10

SA Case Packer, Cartons Form Fill & Seal, RELENTLESS SXS

ULTRA SMART COMPLETE ROUND WIPES IN CANISTERS PACKAGING LINE

Installation, Service, Parts, Delivery & Training, under ONE umbrella

Our complete round wipes downstream turn-key solutions can help you:

- Expand knowhow

- Enhance production efficiency

- Lower costs per unit sold

- Raise output and product quality

- Improve market share and overall profit margins for the business.

It is our belief that the suggested Line is the most advanced in the world today.

Our machines are totally unique, they provide:

- Ultra low downtime

- Sanitary and materials waste control design,

- Complete Originality – our vertical SAS for canisters rolled wipes stuffing is the first of its kind in the market

- Supreme accuracy; the special FGW no-drip, no – ”nonwoven overflow” shower nozzles boast 0.5% accuracy in fill & portion

- The SEALPRO linear cut & conduction seal methodology and the CIW no lids deformation mechanism are also totally unique in the industry.

As you can see These are NOT generic machines but were developed for the specific market needs required for high quality canisters wipes production. SA is your first choice for cans feeding, wipes stuffing, filling, sealing, capping, continuous labeling and case packing.

Quick Fact Sheet:

- As little as 2 operators from the master roll to a canister packed in a box

- Strikingly low changeover downtime, raw materials waste and space requirement design, leading to substantial costs savings

- Throughputs offered in 60, 120 and 200ppm

- NOT just generic machines but equipment designed for the specific market needs of high quality canisters wipes production.