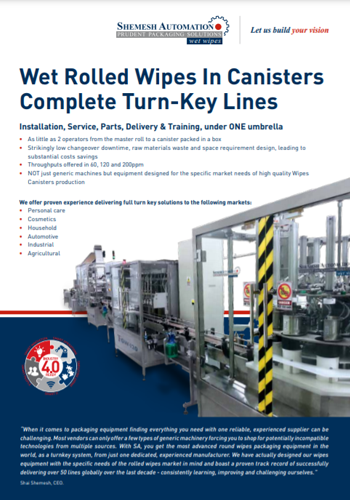

Gallery

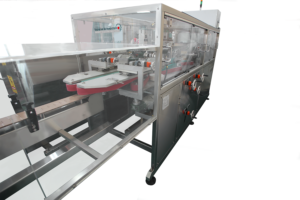

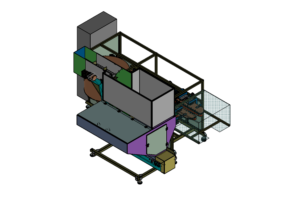

Fully Synchronized Canister Unscrambler

The prolific SA-CF120 Canister Unscrambler, applicable to all common canister shapes and sizes, will ensure up to 120 units per minute reach the conveyor in perfect order.

The fully synchronized container unscrambler reduces the need for manual operation and vastly improves the efficiency and accuracy of your line.

Benefits

- Capacity: up to 120 containers per minute

- Designed for a multitude of container types including both round and oval shaped canisters and bottles

- Elevator Tank for containers: 700-1000 containers (Can be designed to your factory limitations)

- Fully Synchronized

- Contact us for full specifications

Industry 4.0 Ready

All of Shemesh Automation’s start-of-line systems are Industry 4.0 Ready We’ve taken all the top-of-the-line machinery you have come to expect from SA and enhanced it with smart and autonomous systems fueled by data and machine learning.

Every machine in the range boasts a SECOMA Site Manager 1139 modem, integrated into the machine HMI to enable SMART remote support, live stats and performance analysis as well as manufacturer enhancement feedback.

Once again, you can trust Shemesh Automation to keep you ahead of all of the latest industry trends.

How The SACF Canister Unscrabler Works

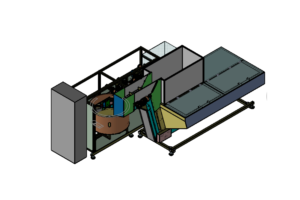

The flagship product within Shemesh Automation’s range of Front-Of-Line Packaging Solutions is the SACF containers hopper and unscrambler for fully automatic canister feeding.

The SA descrambler fits various types of bottles and requires no additional changeover parts for each different bottle size. It features a top-notch control interface, robust building standards and benefits from SA’s ‘easy to use’ and ‘built to last approach.

Firstly, empty canisters are unloaded into the stainless steel SST304 containers hopper, which has level transmitters for ‘half full’ and ‘empty’.

From here they are collected by an Elevator Conveyor which transports them from to a centrifugal feeding plate. The centrifugal feeding plate performs an initial canisters orientation before manoeuvering them into a side conveyor system for final orientation.

After final orientation, the canisters leave the machine standing vertically and are directed downstream along a conveyor in the perfect position for accurate filling.