Complete Turnkey Solutions - Buckets

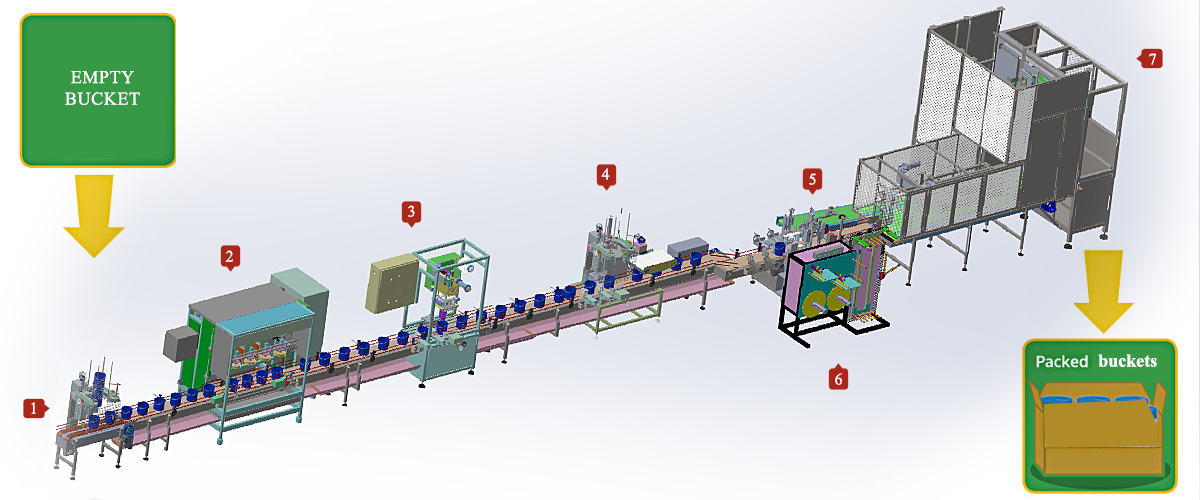

ULTRA SMART COMPLETE ROUND WIPES IN BUCKETS/PAILS PACKAGING LINE

Installation, Service, Parts, Delivery & Training, under ONE umbrella

Team up with the world’s most advanced round wipes downstream equipment maker to expand knowhow, enhance production efficiency, lower costs per unit sold, raise output and product quality thereby improving market share and overall profit margins for the business. It is our belief that the suggested Line is the most advanced in the world today. In addition to Ultra low downtime, sanitary and materials waste control design, Some of the Line components like our flagship first-to-market, special FGW special no-drip, no – ”nonwoven overflow” shower nozzles with 0.25% tolerance of volume accuracy in fill & portion, the SEALPRO linear cut &thermo seal methodology and Lids Denester with top conveyor mechanism are unique in the industry. These are NOT generic machines but were developed for the specific market needs required for high quality bucket wipes production. SA boasts unprecedented proven empirical experience providing one-stop shop turnkey bucket wipes solutions for converting, filling, sealing, lidding, continuous labeling and case packing. From the client’s perspective, this means less responsibility questions, lower costs at the sale and after sale stages and seamless, reliable and efficient operating standard.

Quick Fact Sheet:

- As little as 2 operators from the master roll to a bucket packed in a box

- Strikingly low changeover downtime, raw materials waste and space requirement design, leading to substantial costs savings

- Dosing accuracy of 0.25% of liquid volume- reducing waste!

- Throughput of upto 25 buckets/minute with 3,500ml liquid vol

- NOT just generic machines but equipment designed for the specific market needs of high quality bucket-wipes production.

- 316 Stainless Steel & electro polished steel smart liquid tank