From Roll to Revenue – Watch the 25-Second Video

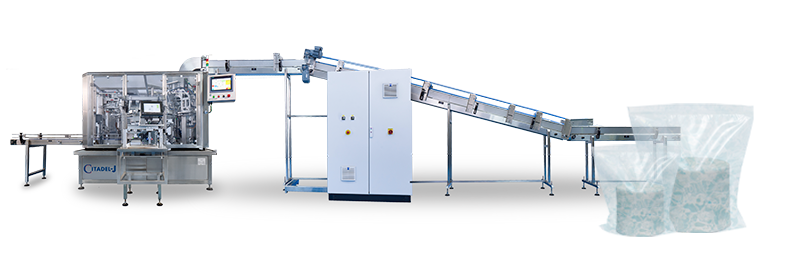

The Ultimate All-in-One Machine for Jumbo Rolls

Forget complex lines. The Citadel-J condenses what used to take multiple machines, operators, and square meters… into a single, compact, intelligent monoblock. That’s the Shemesh difference.

WHY THE CITADEL-J IS A GAME CHANGER

While most packaging lines require 3–5 separate machines, and multiple operators, to handle jumbo nonwoven rolls, the Citadel-J combines everything in one:

- One machine

- One operator

- One smart investment

VALUE DELIVERED:

- Speed: Up to 12ppm for jumbo rolls – unmatched in an all-in-one format

- Simplicity: Fewer operators, less floor space, no manual handling

- ROI: Fast setup, ultra-low downtime, and minimal waste = higher profits

- Quality: Built-in QC and checkweigher for consistent results, batch after batch

- Flexibility: Works with rolls up to Ø230mm and bags up to 500mm height

“It’s not just a bagger – it’s a fully automated packaging brain for jumbo wipes rolls.”

WHAT IT REPLACES

Traditional Multi-Machine Line:

- Jumbo Rolls Feed – lacks an integrated, synchronized feed system for large rolls

- Bags Magazine – no unified flow; components fed manually or via disconnected conveyors

- Bag Opener – custom system, often manual adjustments

- Bag Inflator – standalone air-injection module

- Roll Stuffer – bulky stuffing machine with manual roll orientation

- Liquid Filler – typically separate, risking foam/spill

- Sealing Unit – dedicated top-sealer with extra cooling unit

- Discharge & QC – separate checkweigher & reject system

- Liquid Tank – external or floor-mounted tank

- Roll Inlet System – manual or inline integration

Requires 3–4 machines, 2+ operators, coordination, and more space

WHAT IT REPLACES – SIDE-BY-SIDE COMPARISON

| Traditional Line | Citadel-J All-in-One |

|---|---|

| No synchronized feed system for jumbo rolls | Servo-synchronized jumbo roll unwinder |

| Separate Bags Magazine feed system | Integrated bags magazine and feed inlet |

| Standalone Bag Opener (often manual adjustment) | Servo-controlled bag opening station |

| External Air Inflation Module | Precision air-injection built into turret |

| Bulky Roll Stuffer with manual roll guidance | Smart servo-driven vertical roll stuffing |

| Separate Liquid Filler prone to foaming/spills | Built-in 2-step anti-foam liquid filling from smart tank |

| Dedicated Top Sealer + cooling unit | Automatic sealing + integrated cooling zone |

| Standalone Checkweigher / QC station | QC + reject integrated into discharge station |

| Floor-mounted Liquid Tank | Smart internal liquid tank integrated into the block |

| Manual or inline Roll Inlet system | Fully synchronized servo-driven logs inlet |

| ♂️ Requires 2–3 operators, large floor space | 1 operator, compact monoblock < 2m x 2m |

ALL-IN-ONE CITADEL-J MONOBLOCK

- Integrated Bags Magazine & Feed Inlet

- Smart Bag Opening + Inflation in sequence

- Servo-driven Vertical Roll Stuffing from Logs Inlet

- Proprietary 2-Step Liquid Filling from internal Smart Tank

- Top Sealing + Cooling in one indexed cycle

- Built-in Discharge Conveyor + QC/Reject Station

One operator, one system, one footprint (<2x2m) – for complete jumbo roll packaging.

Explore Smarter Packaging with the Canister Monoblock System

Meet Us at WOW International Conference 2025

July 21 – 24, 2025 | Hilton Columbus Downtown, Columbus, Ohio. Make your appointment here

What We Offer:

- Complete Turnkey Solutions – Canisters

- Complete Turnkey Solutions – Buckets

- Automatic Stacker & Bundler

- End-of-Line Machinery: Case packers, palletisers, and depalletisers.

- Turnkey Packaging Solutions: Custom solutions for all types of containers or packaging, supporting both free-flowing and viscous liquids.

- Monoblock Packaging Solutions: Compact systems integrating feeding, sealing, filling, capping, weighing, labeling, and quality control.

Ready to upgrade your wet wipes production? Let’s talk.

Follow us on LinkedIn for updates on our latest innovations.